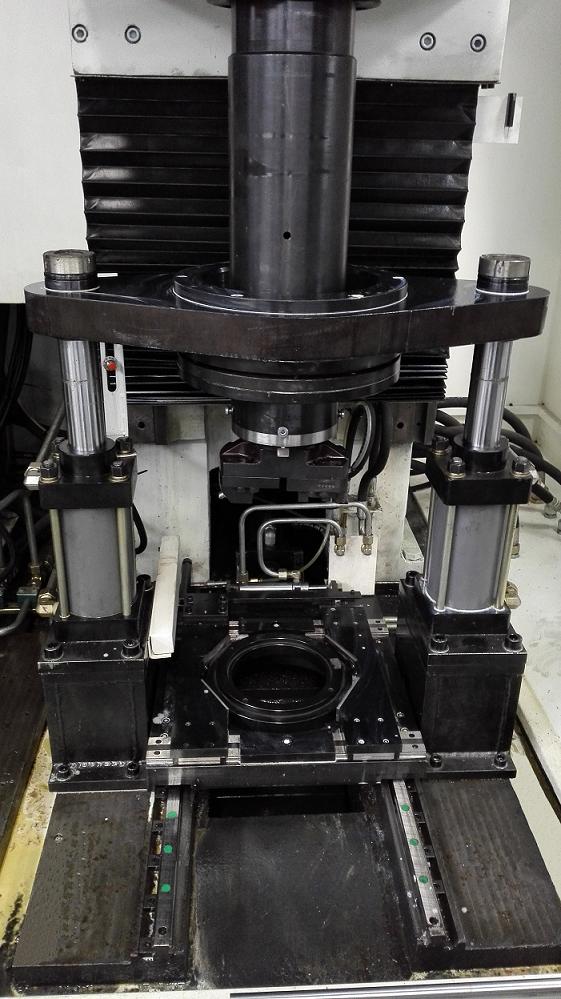

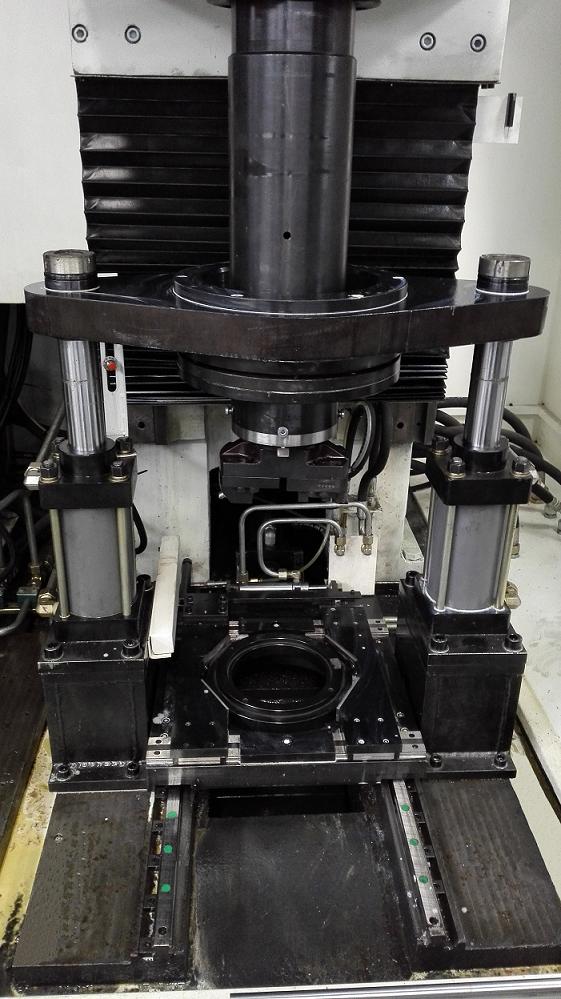

TK515D系列數控高速鏜床

TK515D CNC boring machine

■機床主要部件均采用高強度鑄鐵樹脂砂鑄造��,并采用多次時效處理�,機床剛性好,精度穩(wěn)定����。

■機床主軸采用高剛性的兩點支撐主軸結構,剛性高�����,保證加工剛性足��,加工精度穩(wěn)定����。

■雙軸控制采用獨立系統(tǒng)�,獨立操作面板,可同時完成不同品種工件的加工����。

■機床鏜刀桿及刀夾可根據客戶工件要求訂做�����。刀夾方式靈活多樣�,單刀��、多刀均可使用���。

■具有主軸定向準停功能��,方便單鏜刀退刀�����。

■三色巡視燈便于操作人員觀察機床狀態(tài)��。

■ Machine main components are made of high-strength cast iron casting resin sand, and several times with aging treatment, machine tool rigidity, accuracy and stability.

■ Spindle supported at two points with high rigidity spindle structure, rigidity high enough to ensure that the processing of rigid, precision and stability.

■ Independent axis control system, an independent panel, to be completed at the same time the processing of different varieties of the workpiece.

■ Machine boring bar toolholder and the workpiece can be customized according to customer requirements. Toolholder flexible and diverse, single-pole, multi-tool can be used.

■ Exact stop having spindle orientation function, convenient single boring tool retract.

■ Tricolor patrol lights to facilitate the operator to observe the machine state.

■一個底座上布置獨立的雙立柱���、雙主軸結構,布局合理緊湊�����,可同時加工兩個或兩種零件,加工效率高��,占地面積小�����,又能減少操作工�。

■ One base arranged separate double column, double spindle structure, reasonable layout and compact, it can be processed in two or two parts simultaneously, high efficiency, small footprint, and reducing operator.

■機床采用液壓下壓式夾具、自動定心裝置�、前后送料方式,送料滑軌采用直線導軌����,液壓油缸推動??筛鶕蛻粢笥喿觥?br />

■ Hydraulic machine under the pressure clamp, automatic centering device, before and after the feeding mode, feeding linear guide rail, hydraulic cylinders push. It can be customized according to customer requirements.

■機床配置鏈板式排屑器�����、集屑小車�����,方便加工鐵屑的收集����。

■ Machine configuration chip conveyor chain plate, crumb car, easy to process iron collection.

■主軸滑臺采用滾柱式直線導軌支撐,伺服電機和滾珠絲杠直聯(lián)驅動�����,加工進給快速穩(wěn)定����。

■ Spindle slide support the use of roller linear guide, ball screw and servo motor direct drive, fast and stable machining feed.

■本機床采用全數字式數控系統(tǒng),易于實現(xiàn)進給過程的分段控制��,控制精度高���,穩(wěn)定性好��,易于實現(xiàn)加工過程自動化����。

■ The machine uses fully digital control system, easy to implement segmented feed process control, control of high precision, good stability, easy to implement process automation.

■主軸旋轉運動采用伺服主軸電機驅動�,可實現(xiàn)無級變速。

■ Spindle rotation motion by servo spindle motor drive, can achieve stepless control.

TK515D系列數控高速鏜床規(guī)格參數

|

項目

|

TK515D

|

TK520D

|

|

鏜孔直徑范圍

|

Φ70mm~Φ160mm

|

Φ150mm~Φ210mm

|

|

主軸箱最大行程

|

300mm

|

500mm

|

|

最大鏜孔深度

|

400mm

|

600mm

|

|

主軸連接方式

|

盤式連接

|

|

主軸兩導軌中心距

|

500mm

|

|

兩主軸中心距

|

930mm

|

|

主軸中心線至導軌面距離

|

400mm

|

|

主軸端距工作臺最大距離

|

900mm

|

1000mm

|

|

主軸端距工作臺最小距離

|

300mm

|

400mm

|

|

進給電機功率

|

2.2KW

|

3.5KW

|

|

進給電機扭矩

|

25Nm

|

44Nm

|

|

絲杠螺距

|

10mm

|

|

快速進給速度

|

15m/min

|

|

主軸轉速范圍

|

20-1500rpm

|

20-1200rpm

|

|

進給速度范圍

|

0.01-10mm/r

|

|

主軸電機功率

|

5.5KW

|

7.5KW

|

|

主軸最大扭距

|

95.6Nm

|

140Nm

|

|

電氣控制系統(tǒng)

|

凱恩帝/新代數控系統(tǒng)(選配)

|

|

液壓系統(tǒng)

|

集成式液壓站

|

|

冷卻排屑系統(tǒng)

|

鏈板式排屑器

|

|

潤滑系統(tǒng)

|

集中定量自動潤滑

|

|

氣動系統(tǒng)

|

標準氣動控制系統(tǒng)

|

|

加工精度

|

IT7

|

|

夾具夾緊方式

|

液壓下壓夾具�����、自定心機構、氣動膠套抱緊

|

|

機床防護

|

全封閉式防護

|

|

工作燈

|

節(jié)能型工作燈

|

|

機床噪聲

|

<75db

|

|

機床顏色

|

機座:深灰色���、其他:白色

|

|

機床總功率

|

20KVA

|

25KVA

|

|

機床凈重

|

7000KG

|

8700KG

|

|

機床外形(長×寬×高)

|

2134×2160×2850mm

|

公司官方網站

公司官方網站

微信公眾平臺

微信公眾平臺